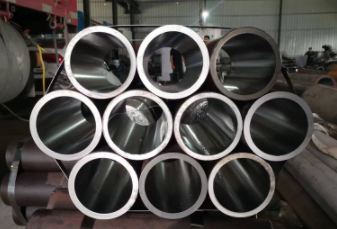

Outlet High Precision Mirror Inner Hole Honing Pipe

Specifications

Hydraulic Tubes Material Standards

| Our Material | Material No. | Similar International Grade | Suitable for… |

| JIS G3445 STKM13C | ASTM MT1020 / BS ERWC3 / DIN ST45 / NF TU37b / ISO TS4 | Carbon steel tubes for machine structural purpose | |

| DIN 2391 ST52 | 1.0580 | JIS STKM19A / ASTM 1524 / EN E355 / ISO TS18 | Mechanical and automotive engineering |

| ST52 BK+S | 1.0580 | Low deformability without heat treatment after cold forming process and stress-relief annealing | |

| DIN 2393 ST52.3 | 1.0570 | ISO Gr.1 | Construction of chemical plant, pipe work and mechanical engineering use |

| ASTM A106 | 1.0405 | JIS STPT410 / BS HFS410 / DIN ST45.8 / NF TU42c | Seamless carbon steel pipe for high temperature service Suitable for bending, flanging, welding and similar forming operations |

Professional manufacturer of honed tube & chrome rod/bar/shaft, founded in 2006.

We make honed tubes, Cold ROLLED (cold drawn) precision seamless steel pipe, quilted pipe, structural pipe, pneumatic hydraulic pipe, automobile half shaft sleeve pipe, welded pipe.

| Item | Honed Tube |

| Raw material | DIN ST52, SAE1020 |

| Pressure & Temperature Classification | High pressure & temperature piping |

| Inner Diameter | 40mm-320mm |

| Outer Diameter | 50-400mm |

| Thickness | 5-40mm |

| Length | 7000mm |

| Straightness | Max 0.5/1000mm |

| Inside Surface Roughness (Ra) | 0.2-0.4um |

| Tolerance INT | DIN2391 H8 |

Application

Factory was established under modern management system and technologies in 2006. It covers an area of 40,000 sq. meters, plant cover 25,000 sq. meters and building area of 30,000 sq. meters. All processing control include cold-drawn, heat treatment, honing, peeling, grinding, polishing. There are 60sets of advanced equipment and 70+ skilled technical workers, annual output over 20,000tons.

Stable delivery time

If products is in stock , we can delivery after received deposit about 7-15days.

If you need customization service, 100tons goods need 20-25days , 100-300 tons goods need 40-50days ,exceed 300 tons goods need 60 days.

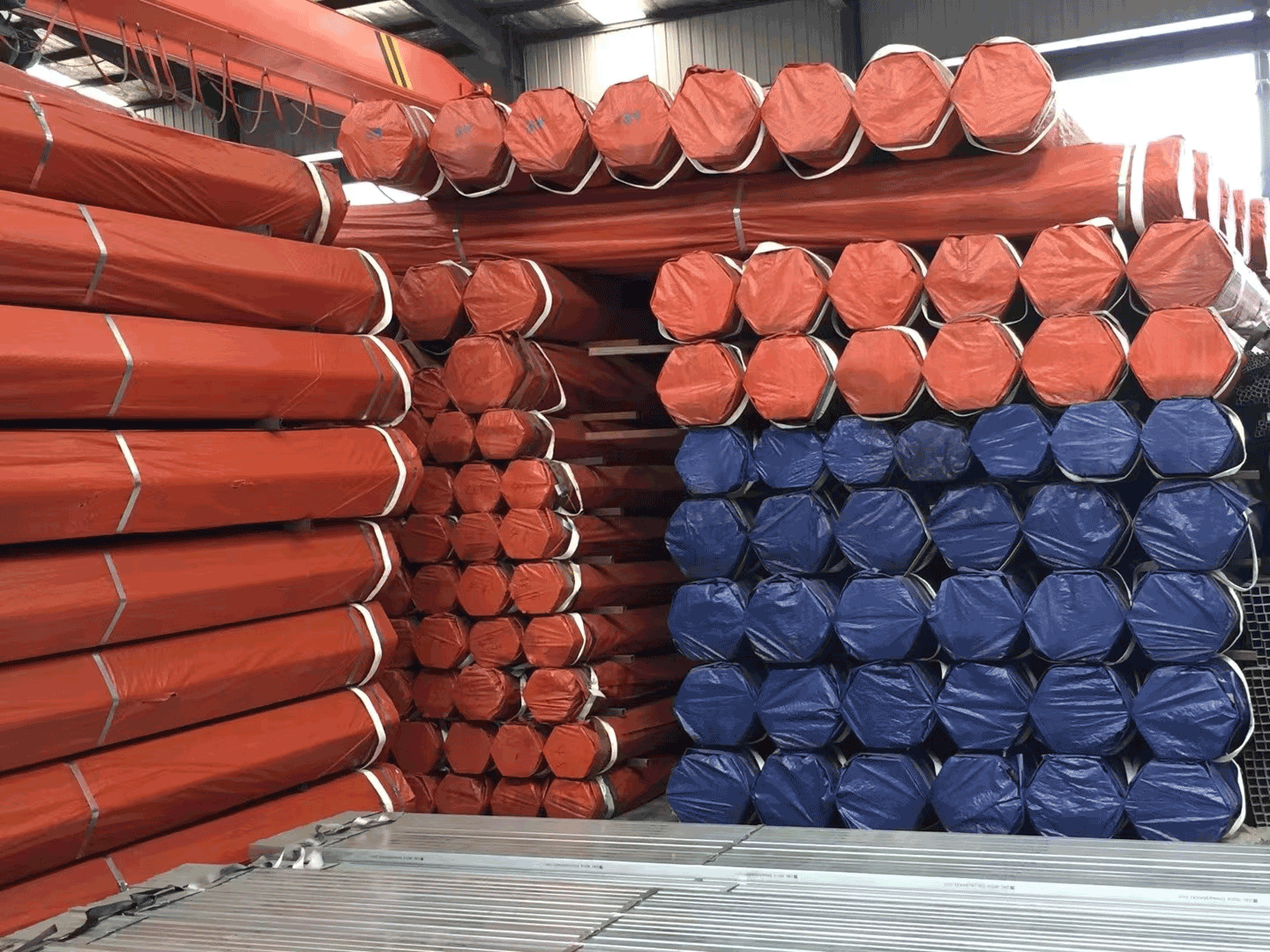

Product packaging material selection is for protect products better.

Honing Cylinder Tubes Quality Standards

Pre Honed Tube & hydraulic cylinder rods exporter in India

- DIN 2391 Seamless Precison Steel Tubes

- EN10305 Steel Tubes for Precision Applications Seamless Cold Drawn Tubes

- ASTM A519 Standard Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

- JIS G3445 Carbon Steel Tubes for Machine Structural Purposes

Pre Honed Tube Steel Grades

ST52 ST45 E355 1020 1026

Ready to Honed Tube Product Processing

Raw materials- Cold drawn/rolled- Heat treatment (BKS)- Honed - packing.

| Processing Way | Cylinder Barrel ID (mm) | Max Length (mtr) | Straightness (mm/mtr) | ID Tolerance | Wall Thickness Tolerance (mm) | ID Roughness (μm) |

| Cold Drawn | 40-320 | 12 | 0.2-0.5 | H8-H10 | ±5% | 0.8-1.6 |

| Cold Rolled | 12-100 | 12 | 0.2-0.5 | H8-H10 | ±5% | 0.8-1.2 |

| Cold Drawn+Honed | 40-500 | 8 | 0.2-0.3 | H7-H9 | ±5% | 0.2-0.8 |

| Cold Drawn-SRB | 40-400 | 7 | 0.2-0.3 | H8-H9 | ± 5% | 0.2-0.4 |

| Deepth Drilling-Honed | 320-1100 | 8 | 0.2-0.3 | H7-H9 | ±8% | 0.2-0.8 |

| Deepth Drilling-SRB | 320-600 | 7 | 0.2-0.3 | H8-H9 | ±8% | 0.2-0.4 |

Honed Seamless Tubes Tolerance Of Inside Diameter

Bright Finish Ready to Honed Tube for Offshore Service

|

Inside dia - specified mm |

10~18 | 18~30 | 30~50 | 50~80 | 80~120 | 120~180 | 180~250 | 250~315 |

| H7 | +0.018 -0 |

+0.021 -0 |

+0.025 -0 |

+0.03 -0 |

+0.035 -0 |

+0.04 -0 |

+0.046 -0 |

+0.052 -0 |

| H8 | +0.027 -0 |

+0.033 -0 |

+0.039 -0 |

+0.046 -0 |

+0.054 -0 |

+0.064 -0 |

+0.072 -0 |

+0.081 -0 |

| H9 | +0.043 -0 |

+0.052 -0 |

+0.062 - 0 |

+0.074 -0 |

+0.087 -0 |

+0.1 -0 |

+0.115 -0 |

+0.13 -0 |

Bright Finish Seamless Honed Tubes Composition Chart

| Grade | C | Si | Mn | P | S | Cr | Mo |

| St 45 (DIN1.0408) | 0.21 max | 0.35 max | 0.40 min | 0.025 max | 0.025 max | / | / |

| St 52 (DIN1.0580) | 0.22 max | 0.55 max | 1.60 max | 0.025 max | 0.025 max | / | / |

| E355 | 0.22 max | 0.55 max | 1.60 max | 0.025 max | 0.025 max | / | / |

| 1020 | 0.18-0.25 | / | 0.30-0.60 | 0.040 max | 0.050 max | / | / |

| 1026 | 0.22-0.28 | / | 0.60-0.90 | 0.040 max | 0.050 max | / | / |

| Si(Max) | Mn (Max) | C Max) | P (Max.) | S (Max) |

|---|---|---|---|---|

| 0.55 | 1.60 | 0.22 | 0.025 | 0.025 |

Mechanical Properties of hydraulic cylinder honed tube

| Grades | Delivery Conditions | Tensile Strength Rm (Mpa) | Elongation in the longitudinal direction Al (%) |

| St 45 | +A (GBK) | 390 min | 21 min |

| St 52 | +A (GBK) | 490 min | 22 min |

| E355 | +A (GBK) | 450 min | 22 min |

| 1020 | +A (GBK) | 390 min | 21 min |

| Tensile strength Min |

Yield Point Min |

Elongation % Min |

|---|---|---|

| 580 N/mm2 | 420 N/mm2 | 10 |

Hydraulic Honed Tubes Excentricity

| Outer Diameter | Excentricity |

|---|---|

| 125 mm | 5 % |

| > 125 mm | 7 % |